SAP Engineers & Consultants

AN ISO 9001:2015 COMPANY

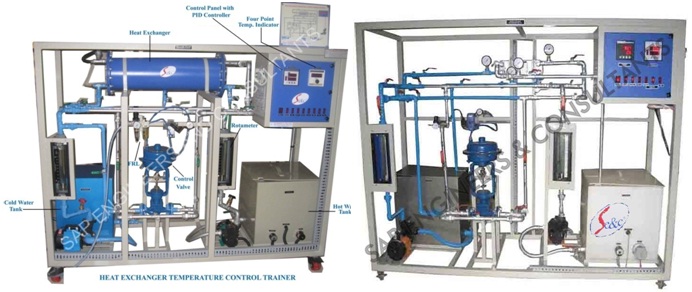

Temperature Control Heat Exchanger

Item Code: PCST-07

The setup outlines the basic of tube and shell type and Plate type heat exchanger feedback temperature control loop.

A " Temperature Control Heat Exchanger frequently basically alluded to as a "heat exchanger," may be a gadget utilized to exchange warm vitality from one liquid to another whereas keeping up exact temperature control. This innovation is commonly utilized in different mechanical forms, HVAC frameworks, refrigeration units, and other applications where the exact control of temperature is basic.

Temperature Control Heat Exchangers offer several preferences over different applications due to their capacity to productively direct and exchange warm between liquids whereas keeping up exact temperature control. Some of the key advantages include:

- Energy Efficiency: Heat exchangers empower proficient heat exchange between liquids, lessening the require for extra heating or cooling gear. This could lead to critical vitality investment funds by utilizing the existing temperature angle between the fluids.

- Minimal Defilement Hazard: Heat exchangers utilize a physical boundary (such as tubes, plates, or coils) to separate the two liquids, avoiding them from blending. This minimizes the chance of contamination and maintains the virtue of each fluid.

- Reduced Working Costs: By productively exchanging heat between fluids, temperature control heat exchangers can offer assistance diminish working costs related with vitality utilization, support, and fluid handling.

- Waste Heat Recuperation: Heat exchangers can be utilized for waste heat recuperation, capturing and repurposing heat that would something else be lost. This can be especially important for progressing vitality proficiency in mechanical processes.

- Flexibility:Temperature control heat exchangers can handle a wide run of fluid sorts, counting fluids and gasses. They can be outlined to suit destructive, gooey, or high-pressure fluids, making them flexible for different mechanical forms.

Temperature control heat exchangers discover applications in a wide run of businesses and forms where exact temperature administration is vital. These heat exchangers are outlined to preserve particular temperatures for different fluids or materials by exchanging heat between them. Here are some common applications:

- HVAC Systems (Heating, Ventilation, and Air Conditioning): Temperature control heat exchangers are utilized in HVAC systems to direct the temperature of air or water that's circulated all through buildings, guaranteeing ideal consolation for occupants.

- Industrial Forms: In different manufacturing businesses, such as pharmaceuticals, chemicals, nourishment and refreshment, and semiconductors, temperature control heat exchangers are utilized to preserve particular temperatures amid generation, responses, and storage.

- Medical Hardware: Temperature-sensitive processes in therapeutic gadgets, research facilities, and investigate offices require exact temperature control. Heat exchangers offer assistance keep up steady conditions for gear and samples.

- Power Generation: Heat exchangers play a crucial part in control plants, making a difference to preserve steady temperatures for cooling water in warm control plants, atomic reactors, and indeed renewable vitality frameworks like concentrated sun powered control plants.

- Environmental Chambers: Testing and investigate offices utilize natural chambers prepared with heat exchangers to simulate different temperature conditions for item testing and investigate.

Temperature control heat exchangers are broadly utilized over different businesses and applications to preserve exact temperature conditions for fluids or materials. Here are a few particular employments of temperature control heat exchangers:

- Industrial Forms: Many mechanical forms require particular temperature control for responses, crystallization, partition, and other operations. Heat exchangers offer assistance keep up steady temperatures, guaranteeing item quality and handle efficiency.

- Chemical Reactors: Chemical responses regularly require tightly controlled temperatures to achieve wanted response rates and item yields. Temperature control heat exchangers help control the warm created or absorbed during these reactions.

- Power Generation: Heat exchangers play a significant part in control plants by overseeing cooling water for turbines, condensers, and other equipment. They offer assistance keep up productive vitality transformation and avoid overheating.

- Automotive Cooling Systems: Radiators and other cooling components in vehicles utilize heat exchangers to control the temperature of motor coolant and avoid motor overheating.

- Waste Heat Recuperation: In businesses where high-temperature squander heat is created, heat exchangers can recover some of this heat for reuse, moving forward in general vitality proficiency.