SAP Engineers & Consultants

AN ISO 9001:2015 COMPANY

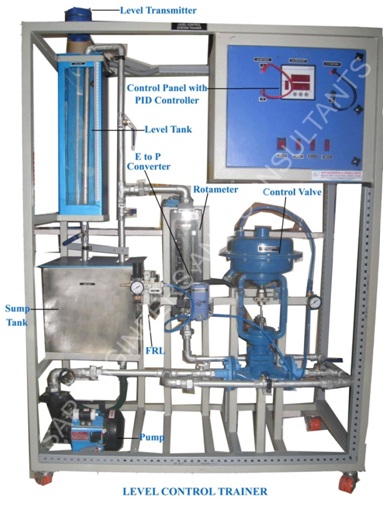

Level Control Trainer

Item Code: PCST-02

The Level Control System Trainer is the system which outlines the basics of closed loop level control process other aspects related to it.

Some Additional Features

- Compact Ergonomic Design.

- Computer Interface & SCADA software connectivity for analysis of Level Control System Trainer (Optional)

- System Dimensions: 4.5 Ft. (L) X 1.5 Ft. (W) X 4.5 Ft. (H)

Services Required

- Water supply and drainage arrangement, Electric supply 230 V AC, 6A, 50 Hz.

- Computer Interface & SCADA software connectivity for analysis of Level Control System Trainer (Optional)

- Clean, Dry Compressed Air Supply at 2.1 Kg/cm²

A " Level Control Trainer typically refers to a training tool or system designed to teach and demonstrate concepts related to level control in various fields, such as industrial processes, fluid mechanics, automation, and more.

The advantages of using a level control trainer can vary based on the specific context and features of the trainer, but here are some common advantages:

- Hands-On Learning: Level control trainers often provide a hands-on learning experience, enabling users to engage with actual or simulated equipment. This practical method improves comprehension and memory of concepts when contrasted with purely theoretical learning.

- Adjustable Parameters: Users can manipulate various parameters in a controlled manner, helping them understand how changes in these parameters affect the level control process.

- Skill Development: Users can develop practical skills related to system tuning, calibration, and maintenance, which are crucial in industries where level control is important for safety and efficiency.

- Real-World Simulations: Many level control trainers use realistic simulations of industrial processes, which provide a safe environment for learners to practice and experiment without the risks associated with real-world systems.

- Flexibility: Trainers can accommodate a range of skill levels, from beginners to advanced users, and can be used for training, demonstrations, experiments, and research.

A Level Control Trainer has a wide range of applications across various industries and educational settings. Here are some common applications of a Level Control Trainer:

- Industrial Process Training: Level control is essential in industries such as chemical, petrochemical, pharmaceuticals, water treatment, and food processing. A Level Control Trainer can be used to teach operators, technicians, and engineers how to effectively control liquid levels in tanks, reactors, and other vessels.

- Automation and Control Engineering Education: In engineering schools and training centers, Level Control Trainers can serve as practical tools for teaching control theory, process dynamics, and automation principles. Students can experiment with different control strategies and gain hands-on experience in designing and tuning control systems.

- Certification and Skill Validation:Industries requiring skilled operators and technicians can use Level Control Trainers as part of certification programs to validate the practical skills of individuals working with level control systems.

A Level Control Trainer has various uses across different contexts, industries, and educational settings due to its ability to provide hands-on learning and practical experience in level control principles. Here are some specific uses of a Level Control Trainer:

- Educational Institutions: Level Control Trainers are commonly used in technical schools, vocational training centers, and universities to teach students about concepts related to fluid mechanics, process control, automation, and instrumentation. They serve as practical tools to complement theoretical knowledge.

- Safety Training: Industries with hazardous processes can simulate emergency scenarios using a Level Control Trainer, helping personnel learn how to respond effectively to critical situations while minimizing risks.

- Research and Development: Researchers can use a Level Control Trainer as a testbed for validating new sensors, control strategies, and measurement techniques in a controlled and repeatable setting.

- Quality Control Training: Industries where product quality depends on precise level control, like food and beverage production, can use Level Control Trainers to educate staff on maintaining consistent levels for optimal product outcomes.

- Maintenance Training: Maintenance personnel can learn how to calibrate sensors, adjust valves, and troubleshoot control loops using a Level Control Trainer, which prepares them for maintaining real systems.

Sap engineers are the best Level Control Trainer product supplier in pune, mumbai, chennai, banglore, hyderabad, ahemednagar at the best prices. These instrumentation and control training equipment are assembled with Computer Interface (Optional), SCADA software that helps in analyzing the flow control system trainer.